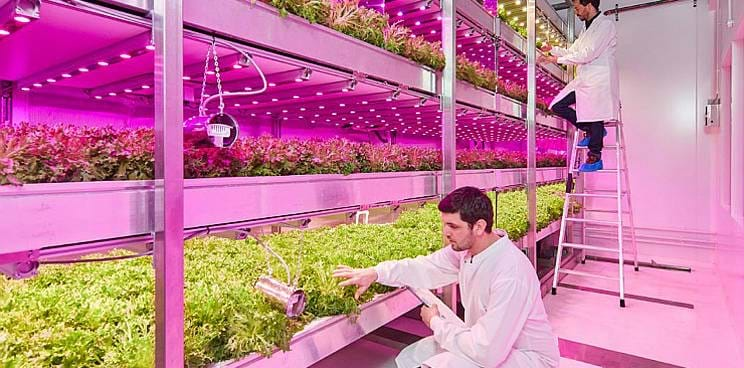

'With vertical farming all year round and 24/7 cultivation'.

Nobody can predict the future, but vertical farming is mentioned as an important development in the growing demand for healthy food. Product engineer Pim de Jong of Codema talks about the advantages and challenges of this form of indoor food cultivation.

Vertical farming is the cultivation of food in stacked culture layers, in a fully controlled environment. Light, energy and water are controlled to grow as efficiently and sustainably as possible, without external influences. This makes it possible to grow indoors at any possible location, such as a factory hall or an office building.

Pim de Jong is involved in the development of vertical farming systems at Codema, where he ended up because of his fascination for complex systems. "Before that, I worked in solar energy and energy storage. When I joined Codema, I was surprised at how advanced horticulture was, and I thought it would be a nice challenge to come up with more and better systems for that. Our Research & Development team deals with various questions. My natural reflex goes to energy, which I find very interesting. And in vertical farming, I saw this as a challenge."

The advantages

In a vertical farm, the grower has complete control over the cultivation area and the cultivation process. This enables the grower to guarantee a reliable supply of fresh products throughout the year. In the closed environment there are of course no external influences and space, energy and raw materials are used as efficiently as possible. This not only saves water and nutrients, but also increases food production with a lower impact on the environment. Vertical farming makes local production possible, which means that less transport is required and emissions can be further reduced. Because of this combination of factors, vertical farms are mentioned as an important way to meet the growing demand for safe food in the future.

"Vertical farming offers solutions for places where it is too hot, too cold or too busy for food production. And for places where the soil is not suitable for agriculture. Look for example at Los Angeles, Oslo or Mumbai. Large cities with a lot of inhabitants where growing food is difficult. Vertical agriculture makes it possible to make the chain from production to consumption much smaller and to provide the population with fresh, healthy food all year round," says De Jong.

The most important challenge

The flow of products is currently the biggest challenge in vertical farms. Organizing the vertical farm in such a way that plants are ripe and can be delivered at the right time. "With heat and CO2 we can influence the growth cycle of plants. A nursery therefore usually works with different departments and temperatures for different phases in the production phase. Also in a vertical farm we can plan in this way that the plants are ripe at the right time. Important developments in this respect are lamps where we can adjust the light spectrum and software with which we can control."

An advantage of vertical farming is that you can produce all year round, without being dependent on the seasons, the weather and daylight. As a result, the production process continues 24 hours a day, an important element in guaranteeing the flow. "The advantage of a fully automated system is the continuous operation of the system, which we can plan with our software and ensure the flow of mature products.

Modular vertical farming system

"Vertical farming is wrongly seen as a pioneer market, even though several companies are already active in it. With its knowledge and experience in water management, lighting, air circulation, climate control, cultivation systems, logistics, software and engineering, Codema has everything in-house to apply in a vertical farm. With its various areas of expertise, Codema is developing a completely automatic, modular system to make vertical farming scalable. In this way, Codema offers the grower all the tools he needs for complete control over food production. Codema's innovations in water management, logistics, climate control, lighting, cultivation systems, software and engineering offer food producers worldwide new answers to business questions.